Handling for Marble and Granite

Suitable for sorting thick strips (up to 20 cm) coming from a previous longitudinal cutter.

Interfaced to the PLC of a cutting line, it picks up the strips cut even at different sizes in width coming from a longitudinal cross cutter and moves them one by one automatically towards the next machine. It also automatically manages the unloading of both the initial and final waste.

Positioned at the exit of an automatic heading machine, it automatically manages unloading of both initial and final waste.

Positioned at the exit of an automatic heading machine, it automatically manages unloading of both initial and final waste.

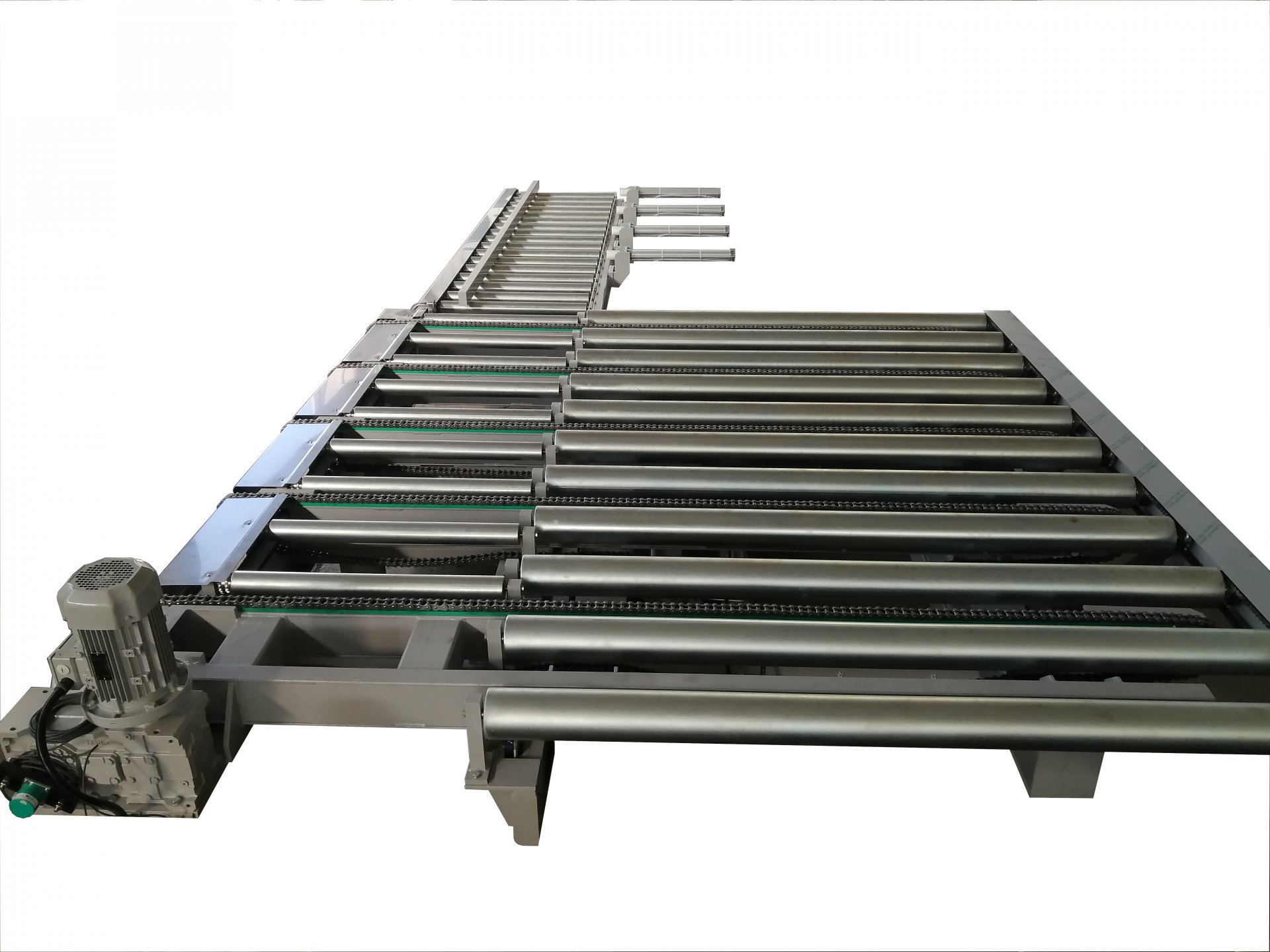

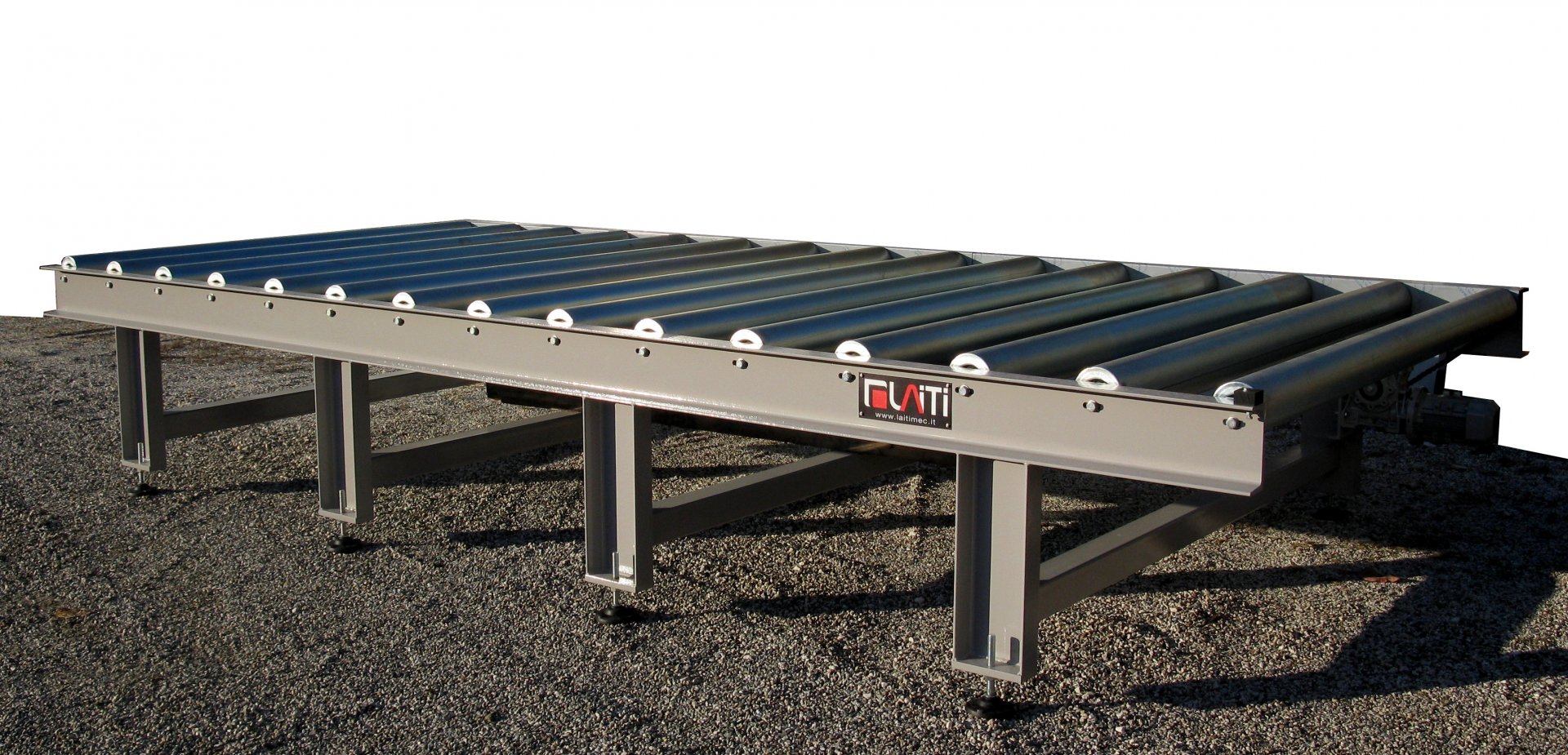

Motorised roller conveyors made to measure, with customisable capacities, lengths and widths.

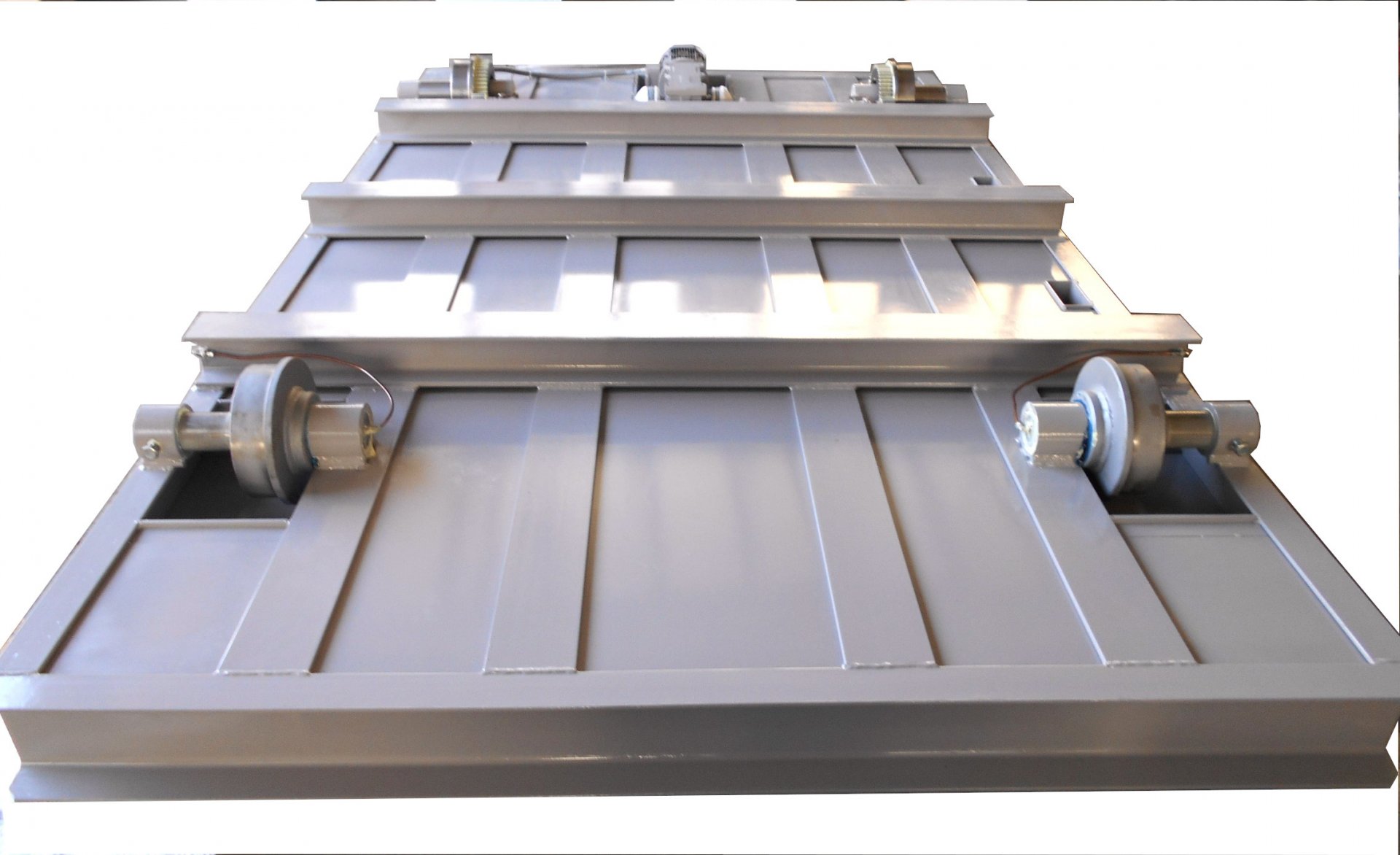

It can be used outbound of a trimming machine to eliminate waste, or under an automatic loader. The two-handed control activates the cylinders that align the material frontally and then advance it.

It is normally used to move rows unloaded from the block size or where passage of small dimensions is required.

FAQ

Yes, Laiti handling systems reduce manual handling and improve safety within the production area.

Yes, they are designed to adapt to different production layouts and existing lines.